Supply chain visibility: how companies spot risk before delays hit

In today’s global market, supply chains have become increasingly complex, making it imperative for companies to achieve comprehensive supply chain visibility to identify risks before they translate into costly delays. As businesses face disruptions from geopolitical tensions, natural disasters, and shifting demand patterns, the ability to monitor and respond proactively has never been more crucial.

Understanding the Concept of Supply Chain Visibility

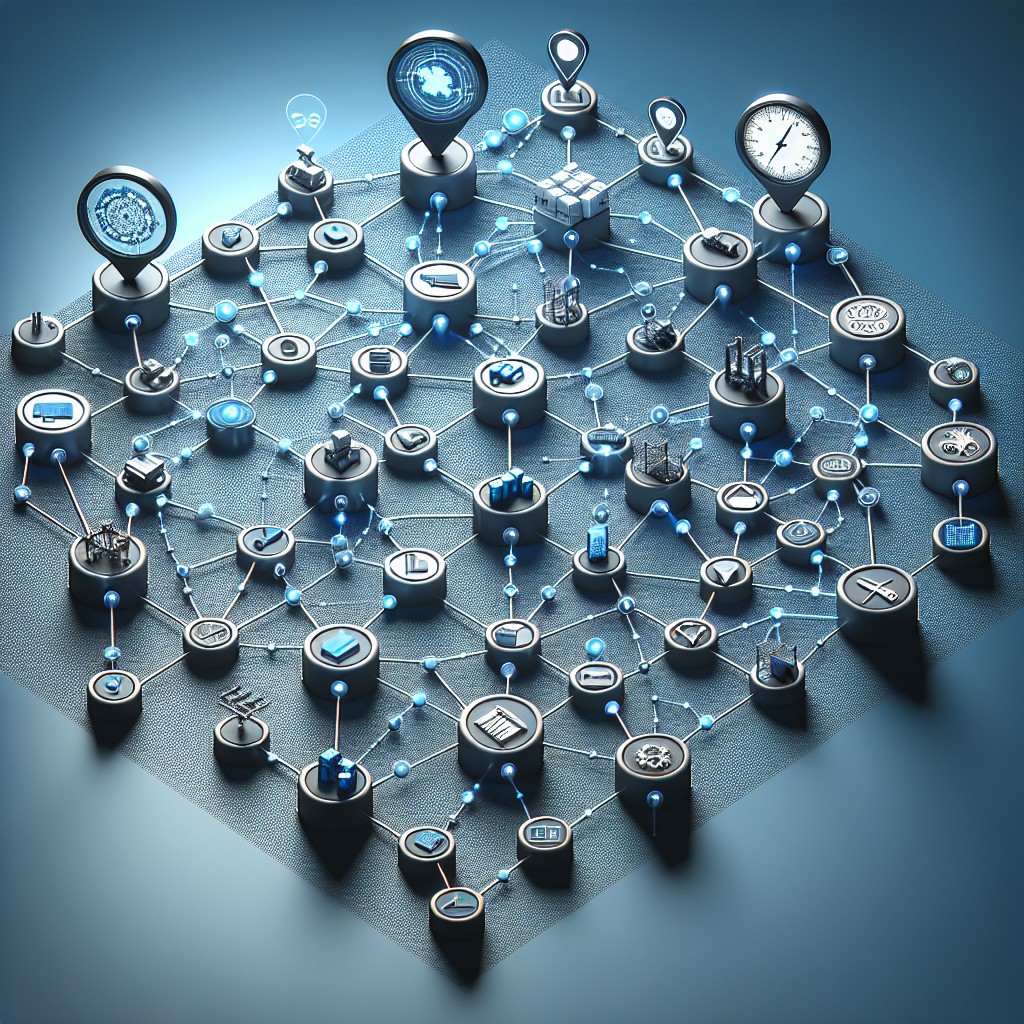

Supply chain visibility refers to the capacity of firms to track materials, inventory, and shipments throughout the entire supply chain in real-time or near real-time. It provides a transparent overview of each stage in the production and delivery process. This transparency enables companies to anticipate potential bottlenecks, quality issues, or logistical problems, thereby minimizing surprises that could impede timely fulfillment.

Technological Innovations Driving Supply Chain Visibility

The rise of digital technologies such as the Internet of Things (IoT), blockchain, and advanced analytics has drastically enhanced supply chain visibility. IoT sensors embedded in products and transport vehicles relay continuous data on location, temperature, and handling conditions. Blockchain technology ensures secure, tamper-proof records of transactions and handoffs, fostering trust and accuracy. Moreover, AI-powered analytics interpret vast datasets to identify patterns indicating emerging risks.

Early Risk Detection: Practical Applications

Companies employ supply chain visibility tools to foresee disruptions well before they occur. For example, if a supplier’s shipment is delayed due to port congestion, real-time tracking systems alert procurement teams to initiate contingency planning immediately. Likewise, predictive analytics can flag quality deviations early by analyzing production data trends, reducing the chance that defective components reach assembly lines. This proactive approach allows firms to adjust sourcing, reroute shipments, or increase safety stock selectively.

Challenges in Achieving Comprehensive Supply Chain Visibility

Despite its clear benefits, attaining end-to-end supply chain visibility is challenging. Many companies operate with fragmented data systems across suppliers, carriers, and warehouses, making seamless information exchange difficult. Data privacy concerns and the competitive nature among supply chain partners sometimes limit willingness to share information openly. Additionally, the integration of new technologies requires significant investment and organizational change management.

The Role of Collaboration and Standardization

To overcome these barriers, industry-wide collaboration and the adoption of standardized data protocols are essential. Initiatives by international organizations and industry groups promote frameworks that facilitate interoperability. Collaboration also fosters a culture of transparency and shared responsibility, enabling all parties to collectively mitigate risks identified through enhanced supply chain visibility. Firms increasingly look to partnerships that can streamline data exchange and provide unified monitoring platforms.

In conclusion, supply chain visibility is becoming a cornerstone for managing risk and maintaining operational resilience in a volatile global environment. As digital tools evolve and cooperation deepens, companies with advanced visibility capabilities will be better positioned to detect disruptions early and safeguard delivery commitments. The future points toward broader adoption of integrated, proactive systems that enable not just reactive responses but strategic supply chain management based on real-time insights and predictive analytics. Ultimately, mastering supply chain visibility will remain vital to maintaining competitive advantage and meeting customer expectations reliably.

Frequently Asked Questions about supply chain visibility

What does supply chain visibility mean for companies?

Supply chain visibility means that companies can monitor and trace their products and processes across the supply chain in real-time, allowing them to quickly identify and address risks before delays occur.

How does technology improve supply chain visibility?

Technologies like IoT sensors, blockchain, and AI analytics provide accurate, timely data and insights, which enhance supply chain visibility by enabling firms to detect issues faster and respond proactively.

What are common challenges in achieving supply chain visibility?

Companies often face fragmented data systems, reluctance to share sensitive information, and high implementation costs, all of which complicate achieving seamless supply chain visibility.

How can supply chain visibility help mitigate risks?

By offering real-time tracking and predictive analytics, supply chain visibility allows companies to foresee delays, quality problems, and logistical issues, enabling early intervention to prevent disruptions.

Where can I find authoritative resources on supply chain visibility?

Reliable information on supply chain visibility can be found on websites like the Supply Chain Digital platform and industry reports from organizations such as the Council of Supply Chain Management Professionals (CSCMP).